Summa F3-Series

The Most Versatile Flatbed Cutting System Ever

Summa’s professional Flatbed Cutting System is an innovative solution for producing a broad variety of signage, displays, samples, packaging applications, and more. With an ever-increasing arsenal of tools and optional add-ons, this is the breakthrough cutting solution you’ve been dreaming about.

Prepress Supply, Inc. is your source for Summa Cutters and supplies in Southern California. Give us a call to set up a virtual or live demonstration on the F-Series Cutter. 714-557-4500

Summa F Series Information

Meet Every Need of Your Customer

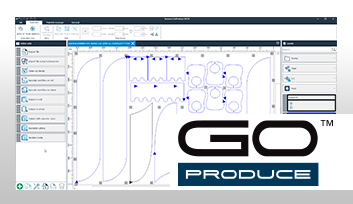

GoProduce 2.0 Software Driving the F-Series

The software GoProduce is developed to handle jobs easy and efficiently. The modern interface with improved navigation enables users to find and operate functions as quickly and intuitively as possible.

Multifunctional Cutting Head for Cutting Efficiency

The multifunctional head can hold up to three modules at one time. The central unit houses a positioning laser and an integrated camera system for fast and accurate contour-cutting mark recognition.

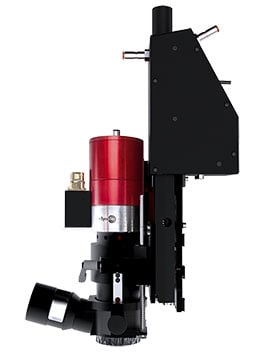

Tangential Module for

Power and Precision

Offering a vertical force of 10 kg and corresponding to a wide range of matching tools. Each tool has a barcode identifier, ensuring automatic recognition and parameter settings.

Advanced Safety System

The advanced Safety System guarantees a safe work environment and is compliant to worldwide health and safety requirements. Thanks to the placement of the system on the top beam, the F Series can be accessed easily, which results in higher production efficiency.

Barcode for Automated Workflows

The barcode automatically identifies the job to obtain the necessary cutting data from the computer. The built-in camera scans the job automatically or by a hand scanner, depending on the selected workflow.

Automatic Depth Control (ADC)

The ADC automatically sets the knife depth and the orientation of the tool. The tip of the knife or bit is measured accurately and the down position of the tool is set to table's level, guaranteeing a flawless cut.

Conveyor extension to minimize downtime

The conveyor extension, optional on the F1612 flatbed cutter, processes cut designs that are much larger than the actual cutting area. While the machine cuts the next part, the first cutout parts can be removed safely at the extended front.

Accelerated workflow with

F-Performance

Increase the performance of your F Series flatbed system up to 40%. Advantages include faster up, down and turning movements of the cutting head, which will be most noticeable and remarkable when using the Kiss-cutting tool.

Heavy-Duty Roll Support

The optional Heavy-Duty Roll Support allows a straight throughput of print rolls onto the wide-format flatbed sizes, F1832, F3220 and F3232. For the processing of heavy banner material and light to non-stretchable wide textile rolls, this roll support will facilitate the operator’s life considerably.

5 Bed Sizes to Fit Any Need

Cutting tables are available in five models. Each of them is bound to significantly increase your productivity.

Something Powerful

Do More For a Whole Lot Less

The Summa F Series flatbed cutter delivers on workflow and throughput, rivaling the industries big brand, high priced solutions. Check out the features in the video to the right. The popular F1612 model is the ideal solution for today's digital shop looking to expand into a profitable flatbed cutting solution.

Prepress Supply, Inc. has the F1612 in-house, ready to demonstrate to you. Email or call us today to schedule a virtual or live demonstration with one of our experienced service or technical sales people. You'll like what you see.

AN ARRAY OF POSSIBILITIES WITHIN EVERY MODULE AND TOOL

The versatility of the F Series flatbed cutters is greatly underlined by the multifunctional head, that is able to hold up to three modules at once. This enables users to perform multiple techniques in one single job, without interruption to switch tools.

ONE MACHINE, FOUR MODULES, COUNTLESS POSSIBILITIES

Drag Knife Module

Make notations with pens or kiss cut a wide range of materials, using a drag knife with a pressure of 600 grams of downforce. Multiple Drag Modules can be put on the multi-functional head to allow both kiss-cutting and drawing without the need to dismount modules.

Ideal for use in the following materials:

- Paper < 200 gsm

- Adhesive vinyl

- Adhesive PVC banner vinyl

Download All Flatbed Tools Overview PDF

Tangential Blade Module

The powerful tangential module is equipped with Summa's True Tangential Technology. It offers a vertical force of 10 kg and a horizontal force of 20 kg. It corresponds to a wide range of matching tools. Each of the many and varied tools have a barcode ID that ensures automatic recognition and parameter settings. Discover all the cutting techniques with the 8 tools that fit in this module.

Available Tools for This Module:

- Kiss Cutting Tools

Single Edge Cutout Tool

Double Edge Cutout Tool

Heavy Duty Cutout Tool

Various Creasing Tools

Various V-Cut Tools

Electronic Oscillating Tool

Pneumatic Oscillating Tool

High Frequency or Standard Router

The High-Frequency Routing Module is equipped with a high-frequency spindle and increased power output, which allows for higher processing speeds. Being perfectly balanced, the high-frequency spindle provides for a much smoother edge finishing of rigid substrates. The routing bit is pneumatically controlled and can be replaced manually in a fast and simple way. This maximizes the productivity of the cutter when processing, for instance, acrylics, wood and plastics.

Standard Router

The Standard Routing Module has a 1 kW motor, capable of handling most solid boards in the graphic and sign industry. Hard foam PVC, acrylic and aluminium covered foam boards as well as other materials, such as wood and MDF can be processed.

High Torque Rotary Module

The High Torque Rotary Module on the Summa F Series is driven by an electronic motor and is capable of handling all kinds of textiles. Thanks to extra rotational power, the HT RM is also able to cut tougher and thicker substrates, such as banner material.

In general, vacuum tables have less grip on textiles. However, the Rotary Knife produces minimal horizontal forces, ensuring the material stays in place. Consequently, extremely porous material can easily be processed with the High Torque Rotary Module.